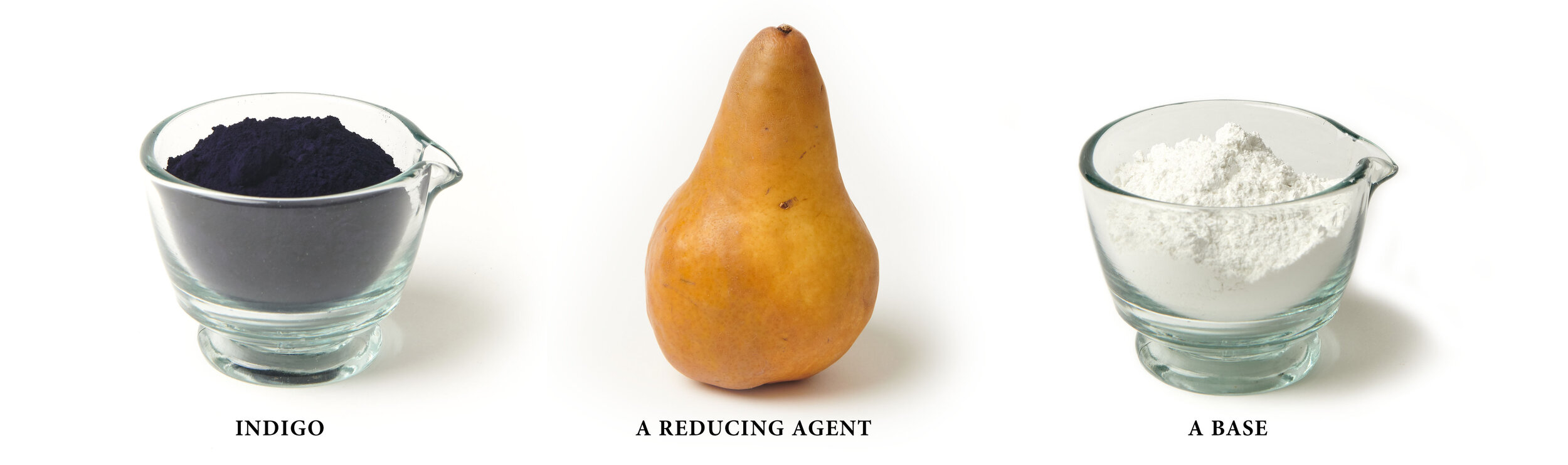

Natural indigo is obtained from a variety of plants, the most widely used one being indigofera tinctoria. This shrub grows wild and is cultivated in tropical areas throughout the world. Indigo powder - the famous blue dye - is extracted from the leaves of the indigo plant. The extract may be purchased as lumps or chips (both of which require grinding before use) or as a fine powder.

Indigo is also available in leaf form - the leaves are harvested, dried and ground into a powder. This form is used as a hair dye and for direct application. We don’t recommend the dried leaf for making these indigo vats.

Indigotin was first synthesized in 1880. Today, synthetic indigo is manufactured from raw materials obtained from the petrochemical industry. It is used on a large scale in the commercial production of blue jeans. Unlike synthetic indigo, natural indigo is extracted from indigo plants. Maiwa gets it’s natural indigo from indigo farms in South India.

Our Relationship With Indigo

Decades ago, Maiwa began looking for blue. The word “indigo” was everywhere, but the legendary dyeplant proved much more elusive. It had been a little over one hundred years since the German chemist Adolph von Baeyer had discovered the chemical formula for indigo and worked out a way to synthesize it industrially. During that time farmers who grew indigo and those who knew how to extract it became increasingly rare.

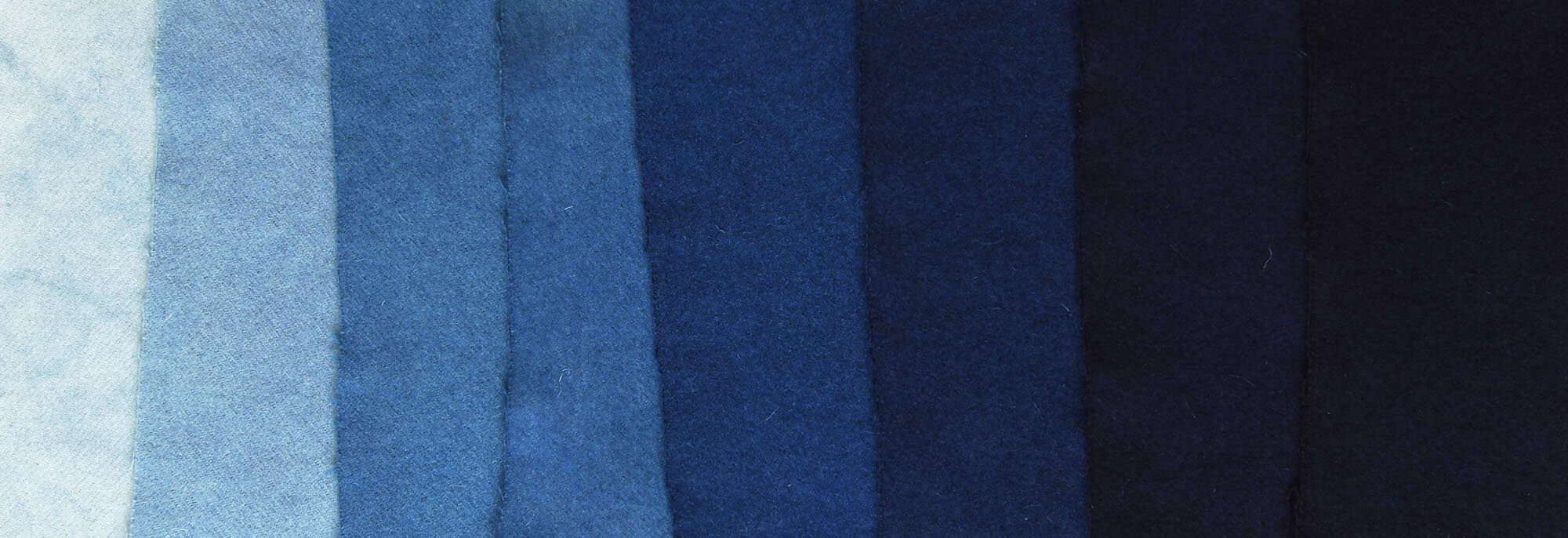

Indigo has great longevity: archeological evidence of its use dates back to Indus valley civilization in the third millennium BCE. Ancient cultures—Greek, Roman, Chinese, Japanese, Indian—all created distinctive textiles based on indigo blue. Remarkably, indigo was also used in Central and South America, where it was independently discovered. Blue seems to be both universal and at the same time deeply tied to the culture that uses it.

Indigo is the first dye we use at Maiwa. When exploring a new relationship with block printers, or scaling up a weaving or dyeing project, indigo is first. In contrast, when we are teaching, indigo is last. The experience of working and dyeing with indigo is so powerful, there is such magic in the process, that if we began with indigo, the students would never move on to the other colours.

It took us years to trace indigo blue back to the fields where it was growing. Each year we would get a little closer. One day, fifteen years ago, someone recommended that we make a trip to Andhra Pradesh in South India. We arrived at a farm and—there it was. There were the fields, the oxcarts working early in the morning to bring in the fresh cut indigo plants. There also were the cement extraction tanks. Decades of processing indigo had stained them a deep blue—as dark as the tropical night.

Maiwa, after thirty years, has formed an intimate relationship with indigo. We have worked with historians like Jenny Balfour Paul, researchers like Dominique Cardon, and botanist-chemists like Michel Garcia. We’ve brought together block printers from Rajasthan and the Kutch desert and placed them in the same natural dye studio as ikat weavers from the south and eri silk farmers from Ethiopia. Indigo connects them all.