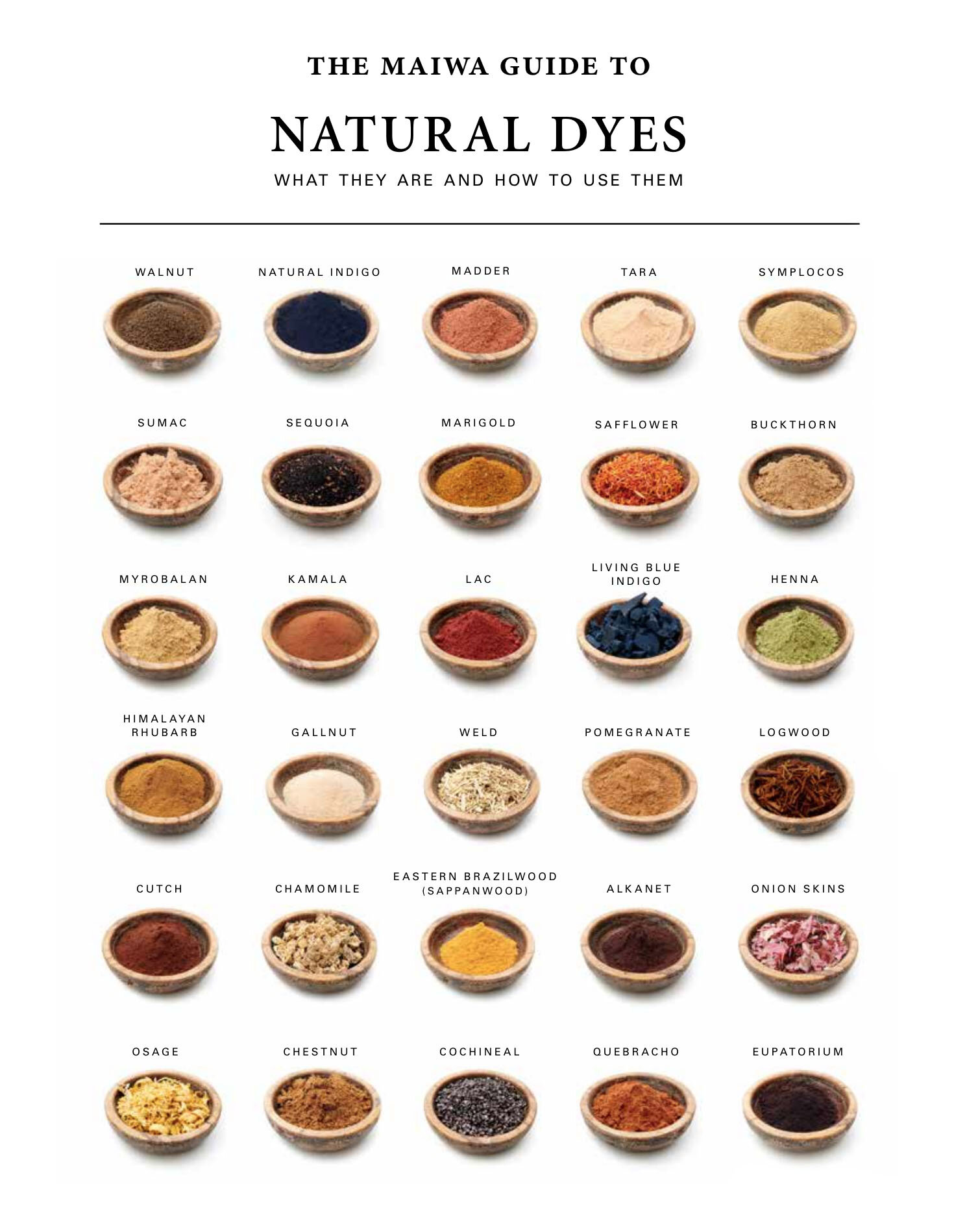

Putting natural colour on cloth involves the use of leaves (such as indigo and henna), barks and woods (logwood, osage), roots (madder, alkanet), flowers (chamomile, marigold, safflower), fruits and nuts (walnut, myrobalan, pomegranate), minerals (alum, iron), and insects (cochineal, lac). These are just some of the classic materials that have been used for thousands of years.

The aromatic steam that rises into the air from the dyepot — especially when working outside on a cool morning — is one of the most compelling aspects of the dyer’s studio. Indeed, working with natural colour is such a sensual experience that many artisans work with natural dyestuff for the sheer pleasure of making the vat. The saturated colours of the immersed materials are also highly photogenic—as is the entire dyeing process.

Maiwa’s obsession with natural dyes is well known. What is less well known is the work that we do behind the scenes each time a shipment of natural dyestuff arrives in our warehouse.

Our role is a bit like that of a master vintner who evaluates multiple grape harvests to make an exceptional wine. We do a complete set of sample tests to evaluate the shade and strength of our shipment. Dyes from natural sources will change with each season. If there has been only little rain one year, the concentration of dyestuff in the plant will alter. So we often combine and blend stocks from multiple years to ensure that the raw dyestuff will yield consistent results.

At Maiwa our policy is to acquire the raw dyestuff in its most elemental form (wood chips, roots, petals) so that we can ensure purity. We then process it into the form (usually a powder) that works best for the artisan dyer. We use natural dyes extensively in our own production, so we can ensure that each package contains a product we would be proud to use ourselves.